Website Development, Software UI Design and Development : CloudNC

Intro

CloudNC automates the CNC manufacturing process using automatic toolpath generation, enabling high-volume production and global shipping. In streamlining this process, thousands of human hours are saved.

I joined CloudNC on a three-month contract in January 2018 to rebuild their website, which was housed in a monorepo with their Autonomous Machining Technology (AMT) software. At the end of the contract, I received positive feedback from the frontend lead and was offered a permanent position on the technology team.

Product Team

I worked in an agile team of six frontend developers and one UX designer, within a 15-engineer full stack team. We had two-week sprints, reporting to the Software Development Team Lead and Head of Product, managed by the VP of Engineering. Using JIRA, we conducted daily stand-ups, fortnightly sprint planning, backlog grooming and retrospectives. Tasks were sized using the Fibonacci sequence to measure progress against a burndown chart.

Key Achievements

My role at CloudNC encompassed three major rebranding exercises:

1. Website Development for Series A Fundraising

To meet a critical need and an external deadline, I worked with one other person to design and build a responsive, optimised website for CloudNC's Series A fundraising. I created mobile, tablet and desktop designs as well as wrote modular HTML and Sass within Angular components for CloudNC's brand website, learning Angular component building, Angular Material, and styling techniques. I ensured best coding practices and attention to detail throughout.

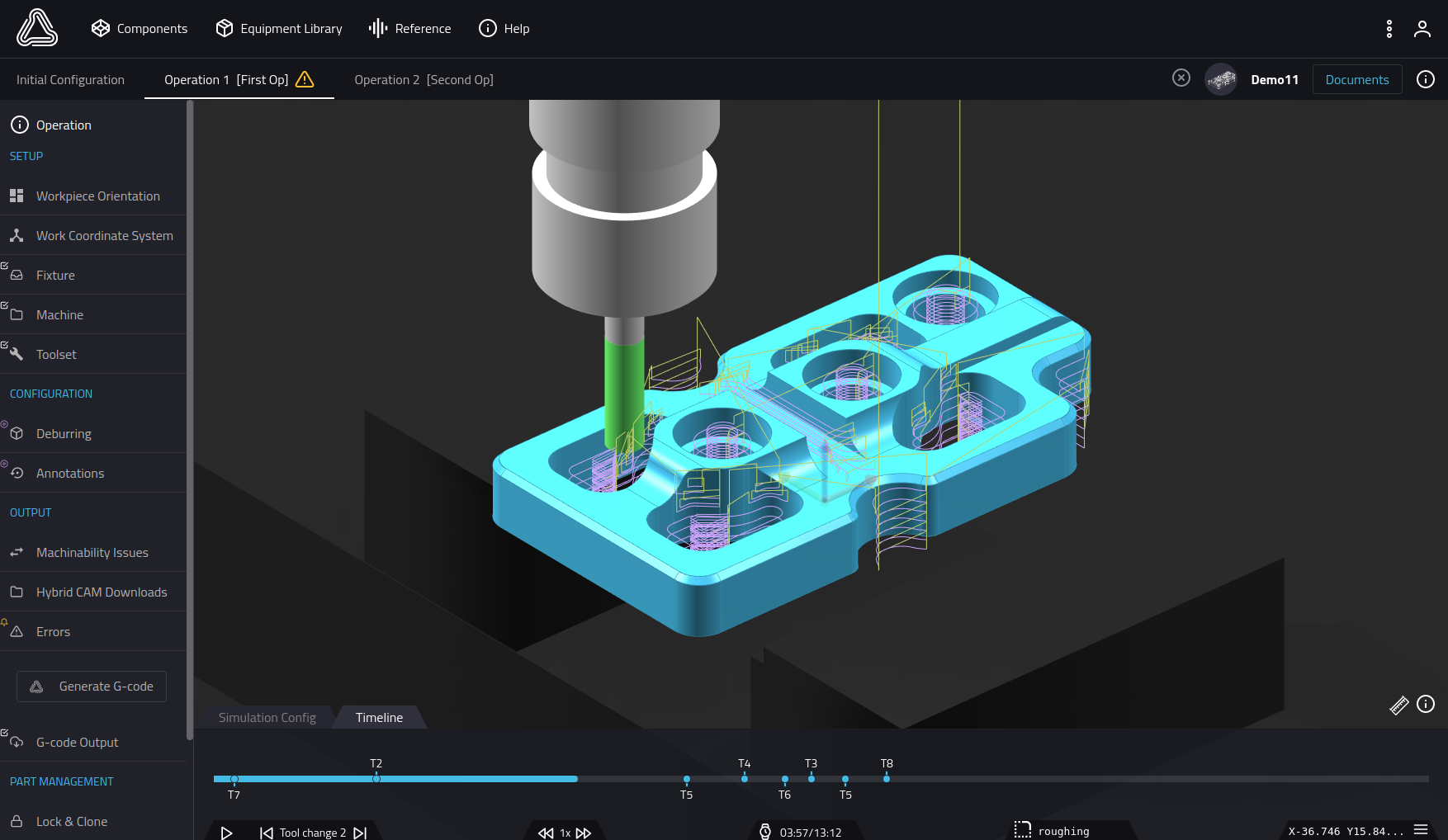

2. B2B SaaS: AMT Software Design and Development

The AMT software is a multi-level, interactive and highly sophisticated CNC machining simulator, g-code generator and tooling library. Integrated with complex mathematical toolpath generation, it takes a 3D file and displays the most efficient toolpaths with the specialized cutting tools needed for manufacturing.

CNC Machinists use this software to generate a setup sheet detailing tool requirements, specifications, and machining times.

I undertook UI design and theming within the software, ensuring design elements were clean and user flows were intuitive.

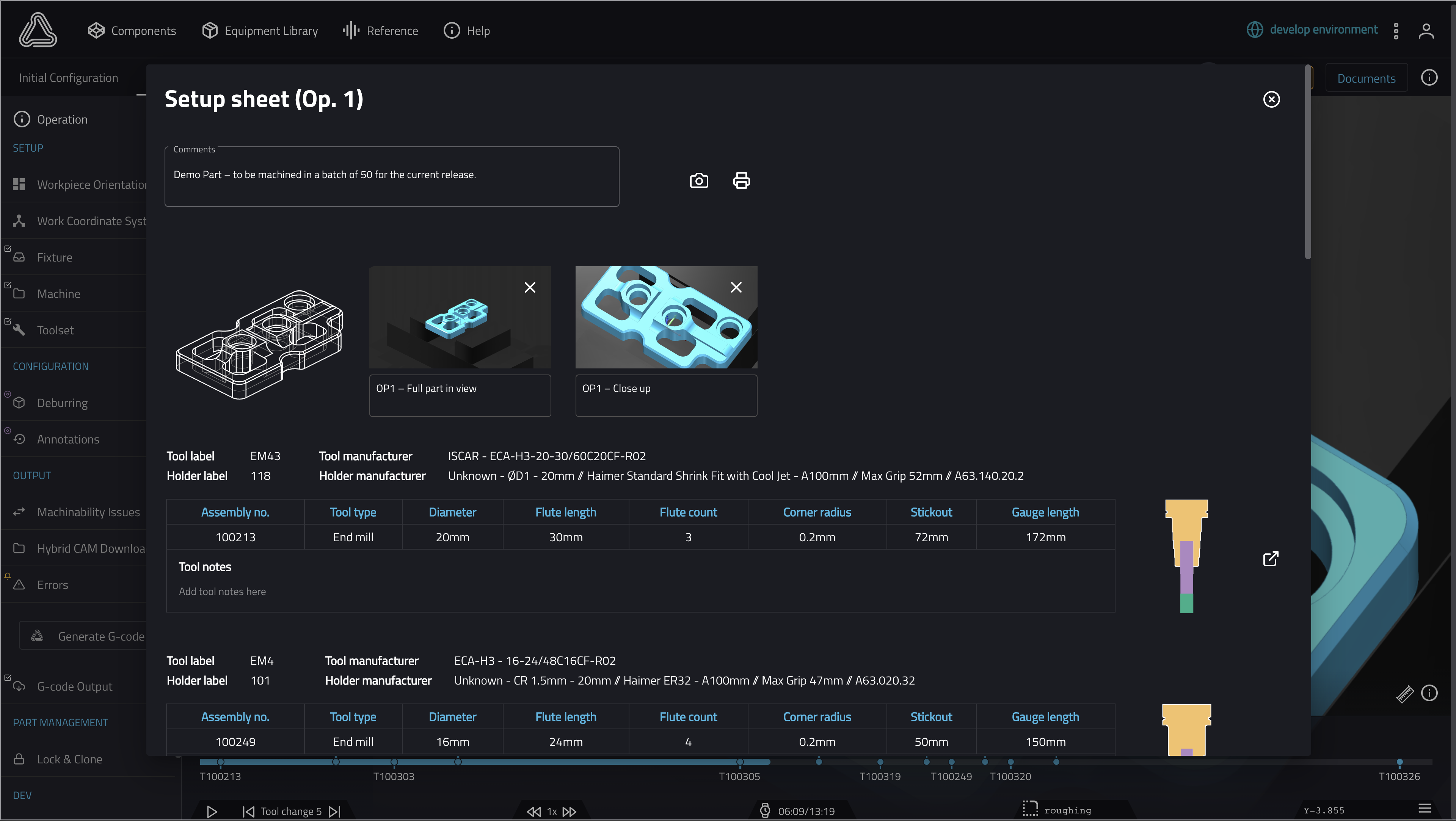

Setup Sheet Redesign

A Setup Sheet guides CNC Machinists on the part being produced, required tools, and estimated machining time. During usability testing, I learnt that the inaugural Sheet lacked key information, was poorly designed and its layout was confusing.

Taking on the role of UX Designer for this project, I iterated on digital and printed templates, improving clarity and logical presentation. The redesigned Setup Sheet was well received for saving time and presenting information more clearly.

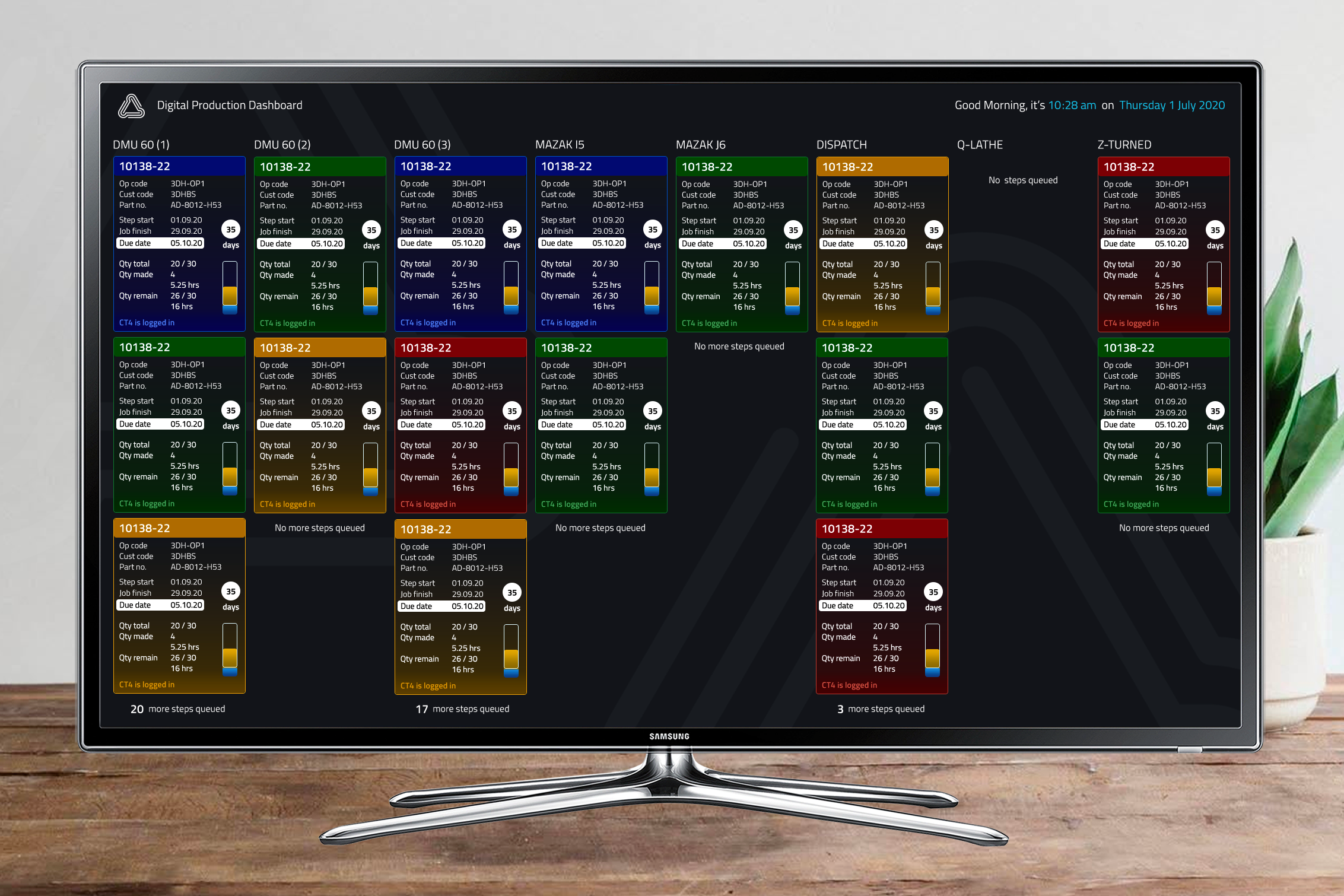

3. UX, UI Design and Project Management for the Digital Production Dashboard

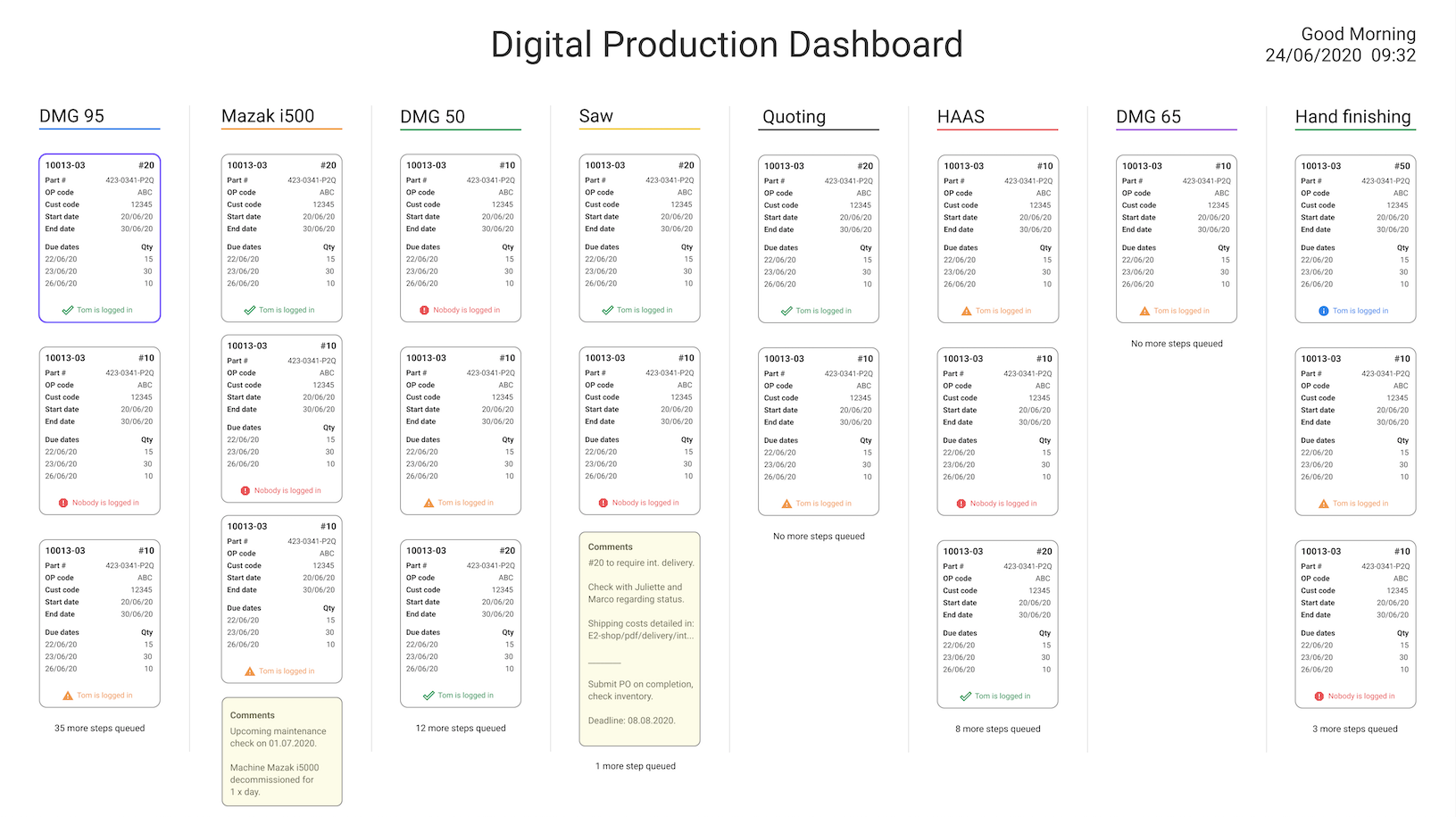

The Operations team needed a real-time dashboard displaying current jobs across work centres (machines or specific job sites) including procurement, quality control, and machine operations. The dashboard, shown on a TV screen, monitored work centre statuses, machining progress and uptime/downtime, capacity, material procurement and planning.

I project managed the design and implementation from start to finish, coordinating with stakeholders and ensured that deadlines were met, in line with business priorities.

In my research, I found there are 48 work centres. Displaying all of thse on one screen seemed impractical, so I opted for two views of 24 centres each, organised in an eight-column grid, with each column containing up to three centres.

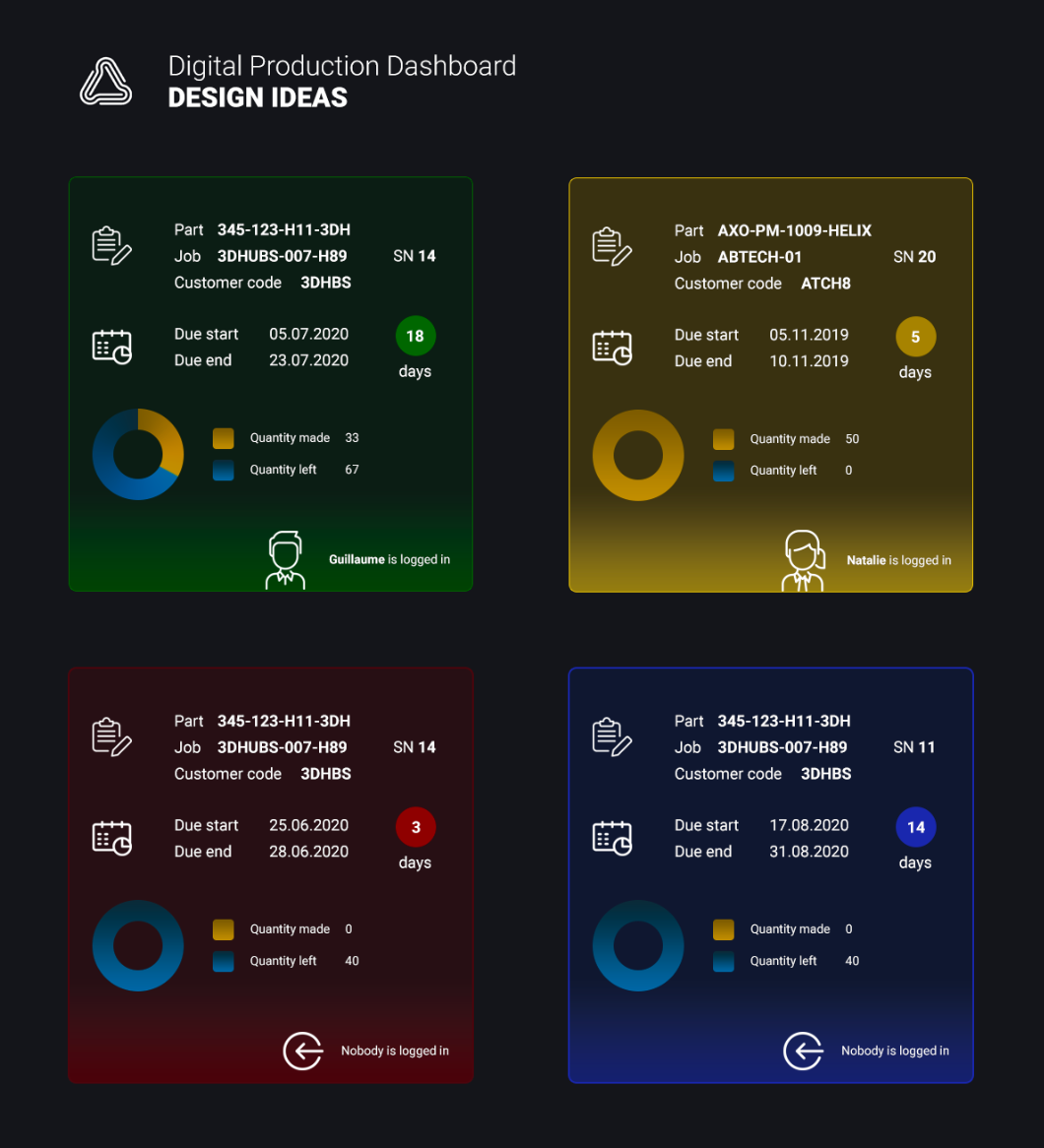

Design Ideas

My initial designs used colors matching the AMT software's UI, as requested by the Operations team. Colours indicated machine status, with clear job/part information displayed.

The initial design was mostly liked but needed adjustments, particularly the doughnut graph, to meet updated requirements. It now shows quantity made in blue, quantity remaining in orange, and total quantity as a white outline.

The single work centre design was well received by the Operations team, who approved it for implementation. It has proven highly effective in monitoring work centre activity and behaviors, enabling factory employees to work more efficiently.